Crushers are used to break down used batteries and electronic components into smaller, manageable pieces, enabling easier material separation, sorting, and downstream processing. But due to the unique risks and challenges posed by these materials, not just any crusher will do.

1. Material Type and Composition

Not all batteries and e-waste are created equal. Lithium-ion, lead-acid, and nickel-cadmium batteries each have different chemical compositions and physical properties. Similarly, electronic waste can range from delicate printed circuit boards (PCBs) to robust casings and cable bundles.

For instance:

Lithium-ion batteries can be volatile, requiring specialized, explosion-resistant crushers.

Lead-acid batteries contain liquid electrolytes and must be processed in equipment that can handle and contain fluids safely.

E-waste such as hard drives, circuit boards, and power adapters often contain a mix of hard metals and plastics, calling for versatile machines with both strength and precision.

TerraSource Global’s portfolio of crushing equipment includes rugged hammer mills and impact crushers that can be tailored to match material characteristics, helping reduce everything from robust battery casings to fine PCB fragments efficiently.

2. Crushing Mechanism

Different crushing technologies offer distinct advantages based on the recycling application:

Shredders: Ideal for bulk e-waste. They produce uniform particle sizes and can handle mixed material streams efficiently.

Hammer Mills: Great for reducing tougher components like metal housings, heatsinks, and batteries to smaller, process-ready sizes. TerraSource’s Jeffrey Rader AB and Flextooth® hammer mills offer robust construction

Impact Crushers: Preferred where controlled particle sizes are needed with lower dust output. These crushers apply high-speed force with reduced vibration, a critical feature when working with sensitive or hazardous materials.

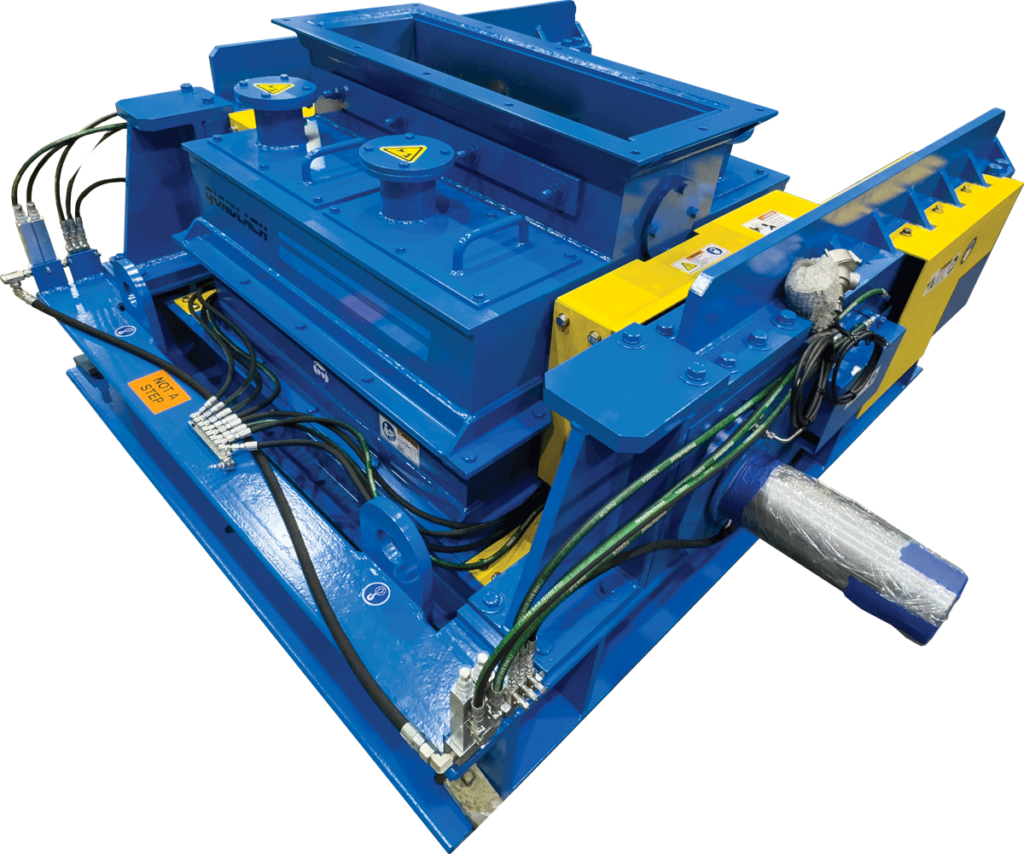

TerraSource’s Gundlach Nanosiz-R® roll crushers also offer tight product size control, making them well-suited for facilities aiming for consistent output sizes with minimal fines—a key advantage in downstream separation stages.

3. Safety Features

When it comes to battery recycling, safety is non-negotiable. Residual energy in batteries can cause short circuits, fires, or explosions if not handled correctly. The right crusher should include:

Spark detection and suppression systems

Explosion-proof electrical enclosures

Inert gas flushing for lithium-based materials

Negative pressure and ventilation systems to control volatile vapors

TerraSource equipment is built with safety in mind, and many units can be configured with enhanced safety features to meet the rigorous demands of battery handling environments.

4. Capacity and Throughput

Recycling operations vary widely in scale, from small local processors to high-volume, industrial-scale facilities. Crushers must match operational needs without becoming bottlenecks. Choose a unit that:

Matches or exceeds your daily throughput requirements

Offers modular scalability for future capacity expansion

Is built for continuous-duty operation with minimal downtime

Many of TerraSource’s crushers can be integrated into automated processing lines and offer modular configurations that grow alongside your facility’s capacity.

5. Environmental and Compliance Factors

Battery and e-waste recycling is heavily regulated. Crushers must not only handle hazardous materials safely but also minimize environmental impact. Look for features like:

Dust suppression systems

Built-in filtration and air handling

Liquid containment for electrolyte runoff

Easy cleaning and maintenance access

With TerraSource’s equipment, dust, fluids, and particulate containment are not afterthoughts—they’re integrated into the design. Our systems help recyclers maintain compliance with EPA and local environmental standards while promoting cleaner, safer workplaces.

Conclusion: Crushing It the Right Way

Selecting the right crusher is more than a technical decision—it’s an investment in safety, compliance, and operational success. With a clear understanding of your materials, desired output, safety needs, and environmental responsibilities, you can choose a crushing solution that enhances every step of your recycling process.

TerraSource Global offers a comprehensive lineup of crushers—each engineered to deliver performance, reliability, and peace of mind in even the most demanding battery and e-waste recycling environments.

Let’s reduce waste the right way—one crushed cell at a time.